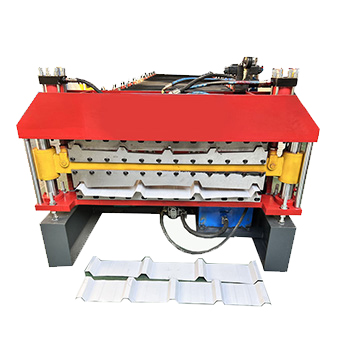

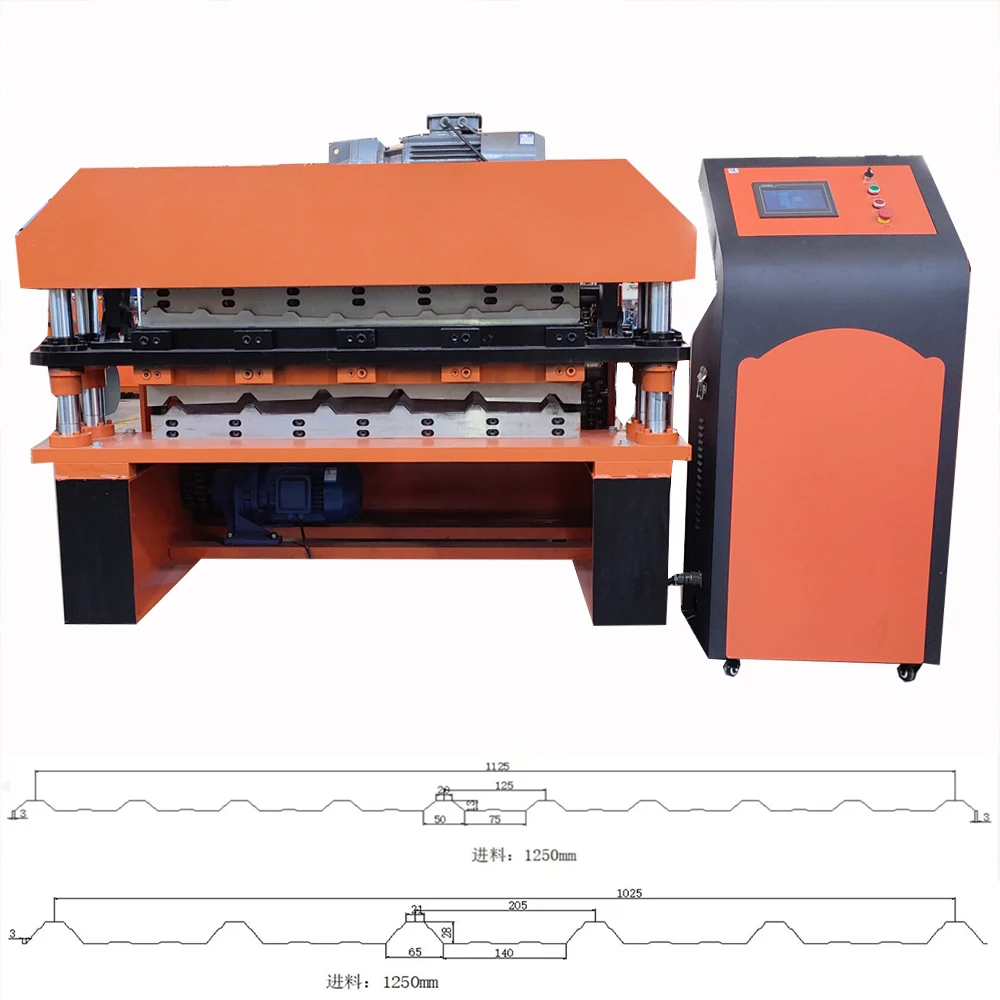

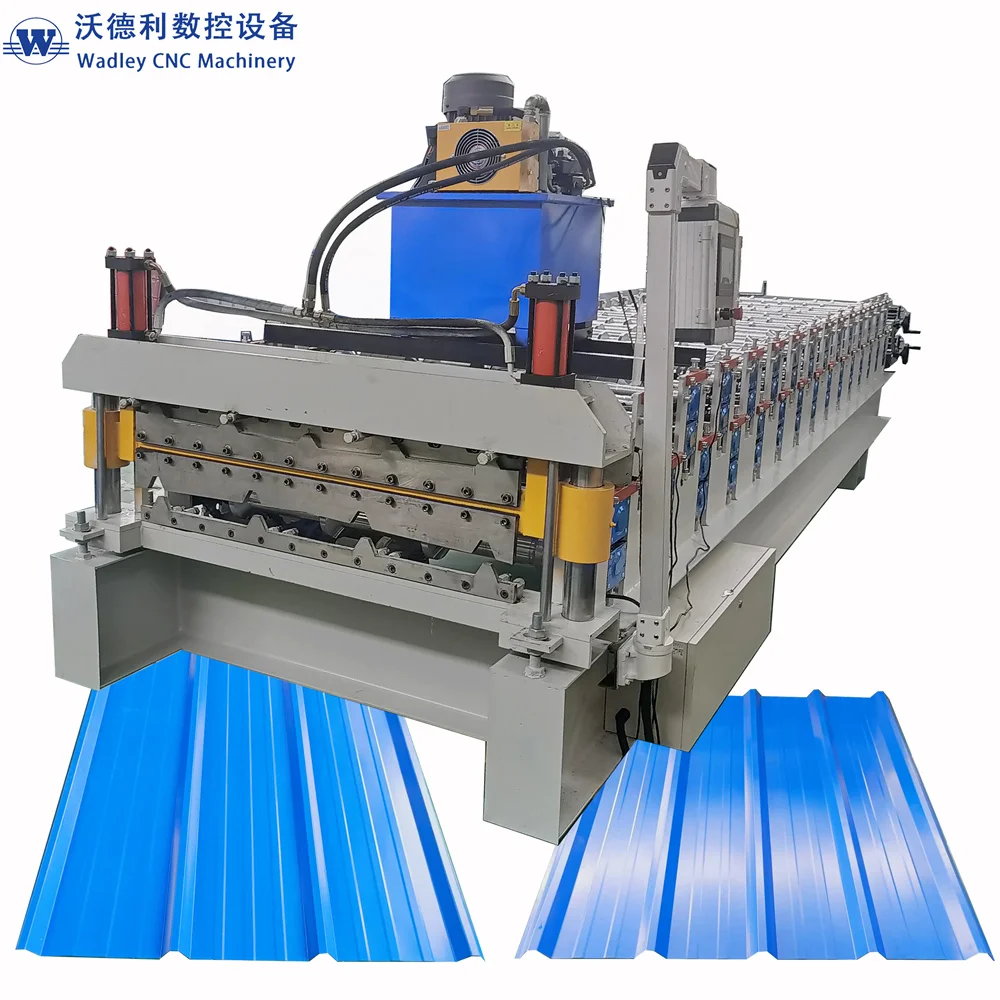

70m/min Single Board Non-stop Cutter Roll Forming Machine

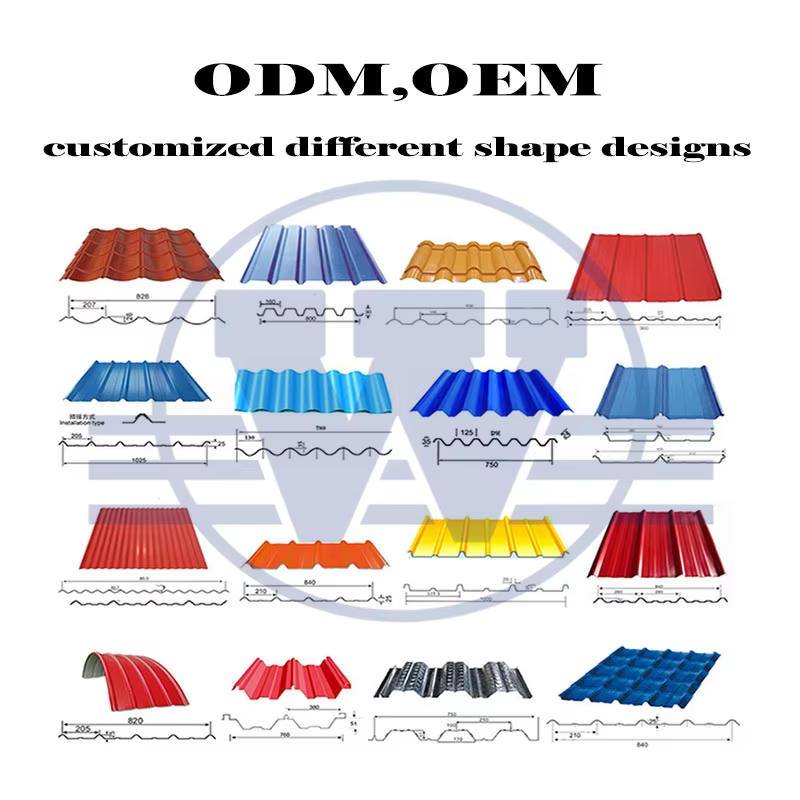

The High Speed Colored Customized 70m/min single board Non-stop cutter roll forming machine and Glazed Roof Tile Making Machine are powerful tools in the roofing industry. They work tirelessly to produce high-quality tiles, enhancing the beauty and durability of buildings. These machines are designed to operate with precision and speed, ensuring efficient production. Whether it's for a large-scale construction project or a small renovation, the High Speed Colored Steel Roof Tile Sheet Roll Forming Machine and Glazed Roof Tile Making Machine are up to the task.

Description

The Non-stop traveller will help the cutter continue working, and mold materials can be customized according to needs to ensure the service life of the equipment.

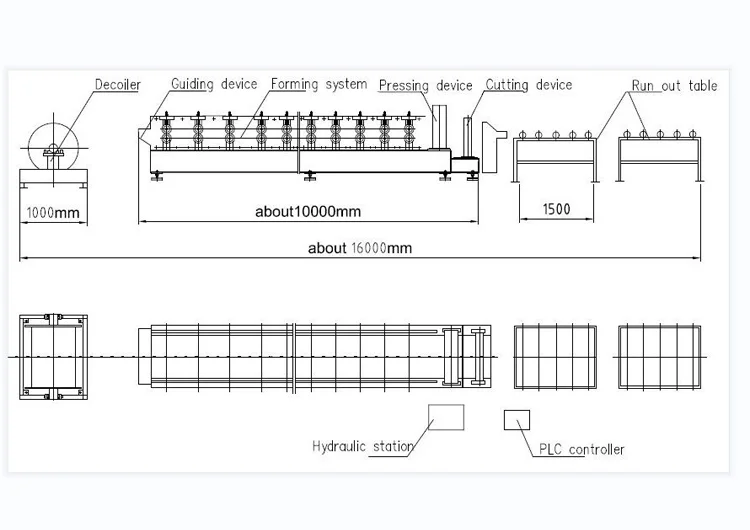

Adopt programmable PLC control system, frequency converter adjustment, simple operation and user-friendly design.Operation Language of PLC can be English, Koran, Russian, Spanish, etc.

The cutting blade of the 70m/min single board Non-stop cutter roll forming machine.Grinding machine grinds it once before using.

Feature:Strong tonnage,high precision cutting

The Non-stop traveller will help the cutter continue working. One worker could operate,simple and high effective

Product Details

- 1 The tile press has the characteristics of light weight, high strength, heavy bearing and good shock resistance.

- 2 The tile press also has the advantages of operation, maintenance, maintenance, mechanical debugging, and easy mold replacement.

- 3 The tile press equipment includes: PLC computer control system, special shearing equipment and hydraulic system. High-level automatic control software is adopted to realize production information management.

- 4 The tile press is mainly suitable for civil buildings of large and medium-sized enterprises, such as factories, stadiums, locomotive garages, hangars, exhibition halls, theaters, etc.

Parameter

|

No |

Item |

Data |

|

1 |

Equipment installation dimensions |

6200mm x 1300mm x 1000mm |

|

2 |

Total equipment weight |

about 3.5T |

|

3 |

Main engine power |

3kw |

|

4 |

Hydraulic shear power |

3kw |

|

5 |

Pressure of hydraulic station |

10-12mpa |

|

6 |

Depth |

840 type 23mm;850 type 8mm pitch: 840 type 210mm;The type 850 130 mm |

|

7 |

Working speed |

0-8m/min |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment