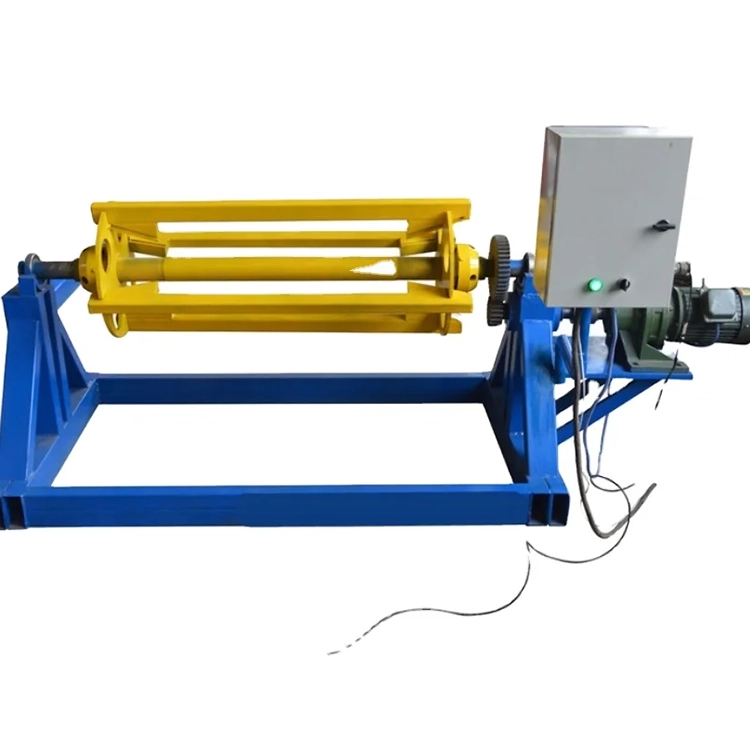

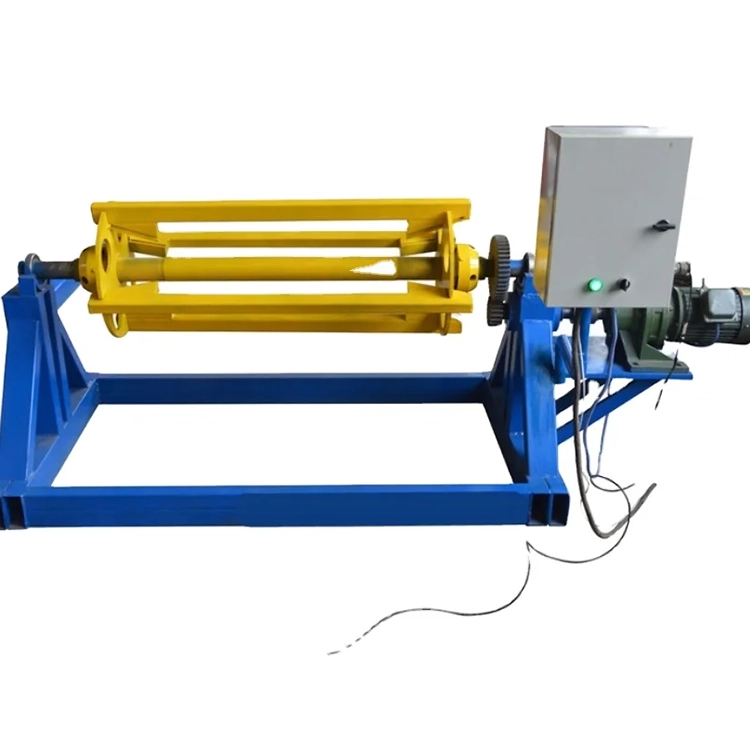

Electric Uncoiler Machine

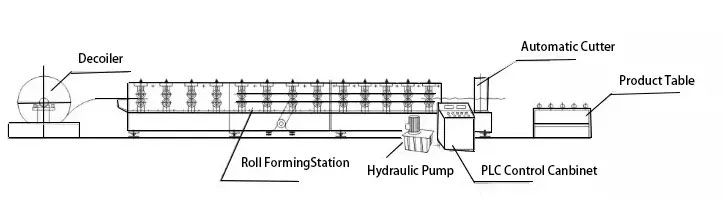

Electric uncoiler is a key equipment of metal coil processing production line (such as slitting line, stamping line, shearing line), mainly used for automatic unfolding of metal coils (steel coils, aluminum coils, copper strips, etc.), providing stable feeding for subsequent striping, stamping or shearing processes.

Description

Electric Uncoiler Machine

An Electric Uncoiler typically consists of a heavy-duty base, a movable coil car, a motor-driven mandrel (expanding head), a hold-down arm/loop controller, an electrical control system (PLC), and necessary safety guards. During operation, the coil car transports the steel coil to the unwinding position, and the mandrel expands to grip the coil's inner diameter. Upon activation, the motor precisely controls the rotational speed based on the main line speed command or downstream tension feedback, enabling active pay-off. The hold-down arm or guide roller helps prevent coil collapse and assists in steering the strip.

Its electronic control system can communicate with the central line controller (e.g., a master PLC) to achieve synchronized operation, automatic edge guiding, closed-loop tension control, and production data logging. Compared to hydraulic drives, the electric solution offers lower energy consumption, faster response, more precise control, and is maintenance-free and environmentally friendly. This equipment is an indispensable starting point for continuous production in various industries, including metal building materials, automotive parts, appliance housings, and packaging products.

Product Details

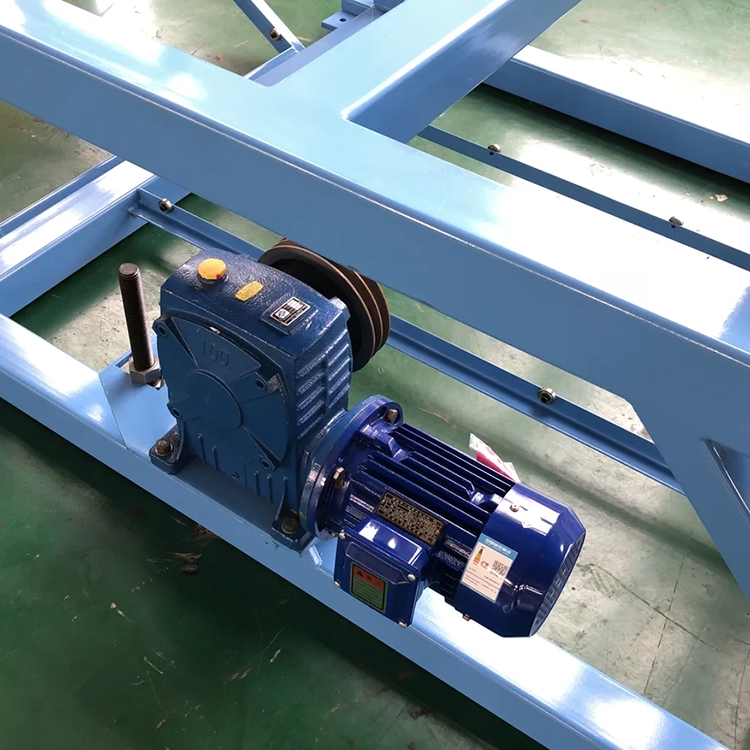

- 1 Electric tightening feeding rack also belongs to a kind of color steel feeding rack, which is more complicated than the simple feeding rack, simple in operation, strong in ease of use, and also attached to brake pads.

- 2 The electric tensioning feeding rack is mainly composed of two parts, the core and the bracket, the two ends of the core have bearings that can rotate freely, the shaft of the core is a solid shaft, strong, no deformation, is the supporting requirements of color steel equipment.

- 3 The electric tensioning feeding rack has the advantages of good corrosion resistance, bright color, beautiful appearance, convenient processing and forming, and has the advantages of the original strength of the steel plate and low cost.

Parameter

| Molde | WL-300 | WL-500 | WL-600 | WL-800 | WL-1000 | WL-1300 |

| width(mm) | 300 | 500 | 600 | 800 | 1000 | 1300 |

| material.d(mm) | 450-550 | 450-550 | 450-550 | 450-550 | 450-550 | 450-550 |

| material o.d(mm) | 1000-1200 | 1000-1200 | 1000-1200 | 1000-1200 | 1000-1200 | 1000-1200 |

| material wight(kg) | 500 | 1000 | 3000 | 5000 | 5000 | 5000-10000 |

| speed of feed | 20 | 20 | 20 | 20 | 20 | 20 |

| motor(hp) | 1 | 2 | 3 | 3 | 4 | 5 |

| machine L*W*H(mm) | 1100*1000*1200 | 1400*1200*1300 | 1500*1200*1300 | 1700*1300*1400 | 1800*1400*1400 | 2000*1800*1800 |

| weight(kg) | 750 | 1000 | 1000 | 11000 | 1500 | 2000 |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment