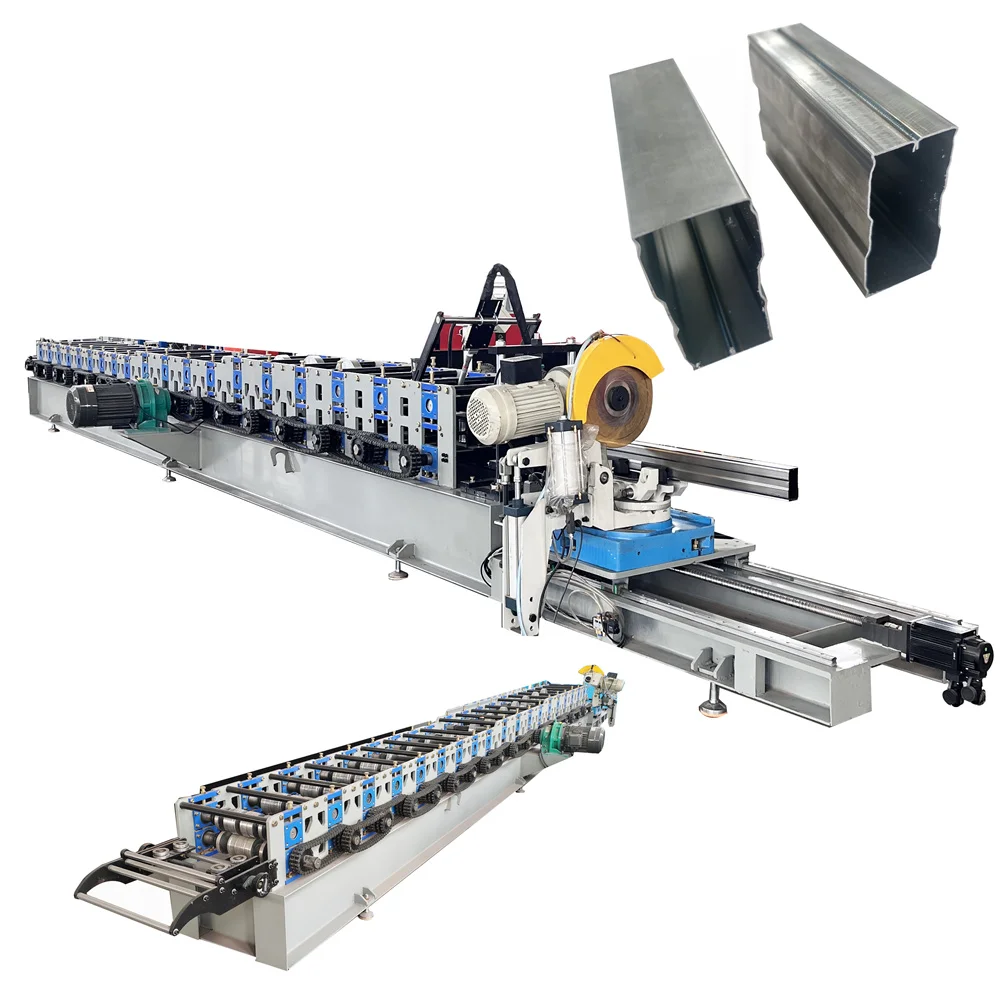

Heavy Duty Shelf Beam Square Tube Welding Roll Forming Machine

High Standard Shelf Column Making Machine is for producing the storage rack for workshop. It can uncoil, level, punch and continuously roll forming with automatic cutting to length.Mostly customers place orders for galvanized and carbon steel that for business construction is more popular.

Description

- High Precision Perforated Shelf Roll Forming Machine Industrial Supermarket Metal Shelve Machine

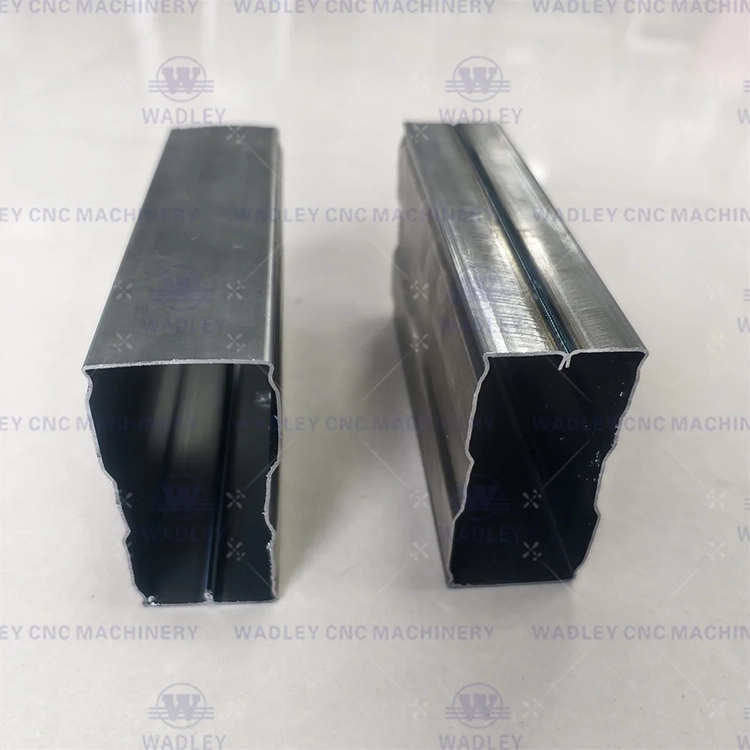

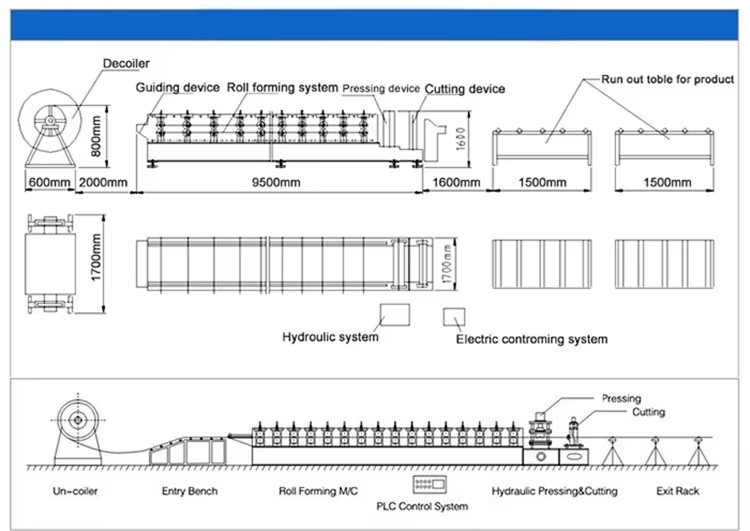

High Standard Shelf Column Making Machine is for producing the storage rack for workshop. It can uncoil, level, punch and continuously roll forming with automatic cutting to length.Mostly customers place orders for galvanized and carbon steel that for business construction is more popular. Pallet racking is usually comprised of beams, wire decks, and uprights. Most common types of pallet racking systems: Cantilever Racking Selective Racking Push Back Racking Drive-In Racking Pallet Flow Racking Carton Flow Racking They are different in the drawing profiles, we can customize the racks according to the customer drawing profiles. This production line consists of de-coiler, servo feeder, hole press, main roll forming machine and hydraulic shear units. And each elements could be designed according to the customer budget like hydraulic decoiler or manual one, gearbox transmission or chain, flying tracking shearing or stop shearing. All those are optional.

Product Details

The Heavy Duty Shelf Beam Square Tube Welding Roll Forming Machine

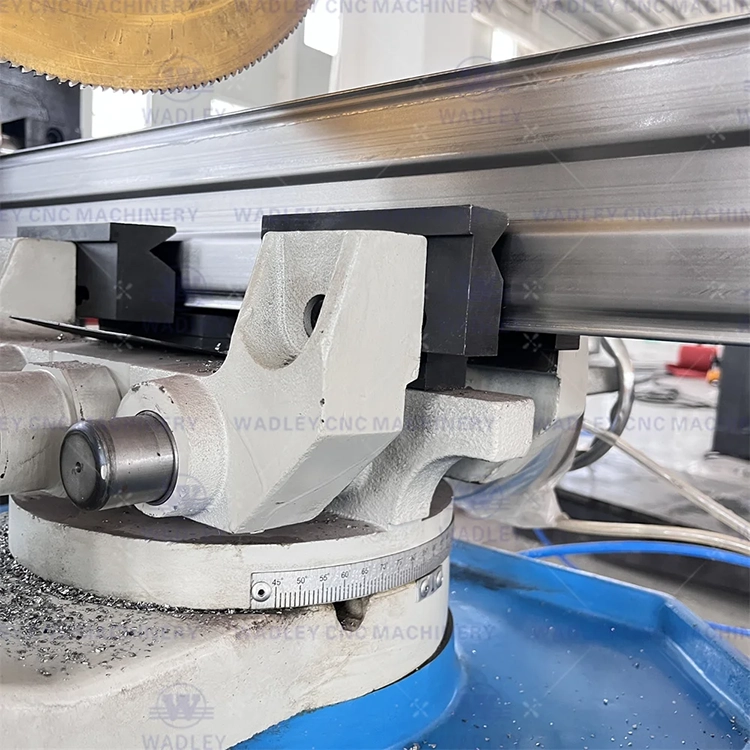

- 1 High Precision Forming – Multi-stage roller dies progressively shape flat metal strips into perfectly square or rectangular tubes with tight tolerances.

- 2 Adjustable Specifications – Supports various tube sizes and thicknesses (0.5–2.0mm) by changing rollers.

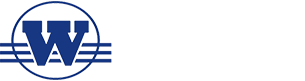

- 3 Automatic Cutting System – Integrated hydraulic or servo cutting unit for precise tube length control (e.g., 1–6 meters).

- 4 Robust Construction – Heavy-duty steel frame and hardened rollers ensure durability and long-term stability.

- 5 High-Speed Production – Operates at 7-10meters/minute, boosting efficiency for mass production.

- 6 PLC Control – User-friendly interface for adjusting speed, length, and tracking production data.

- 7 Material Saving – Optimized design minimizes raw material waste.

Parameter

| Formed Material | PPGI,GI |

| Thickness | Thickness:1-3mm (as customer's request) |

| Roller station | 19rows(As your requirement) |

| Diameter of shaft | 70mm solid shaft |

| Material of rollers | 45# steel, hard chrome plated on the surface |

| Machine body frame | 16mm |

| Cutter | DC53 material, no scratches, no deformation |

| Motor Power | 11KW |

| Hydraulic system power | 7.5KW |

| Voltage | 380V 50Hz 3Phase(As your requirement) |

| Control system | PLC |

| Forming Speed | 7-10m/min(customized) |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment