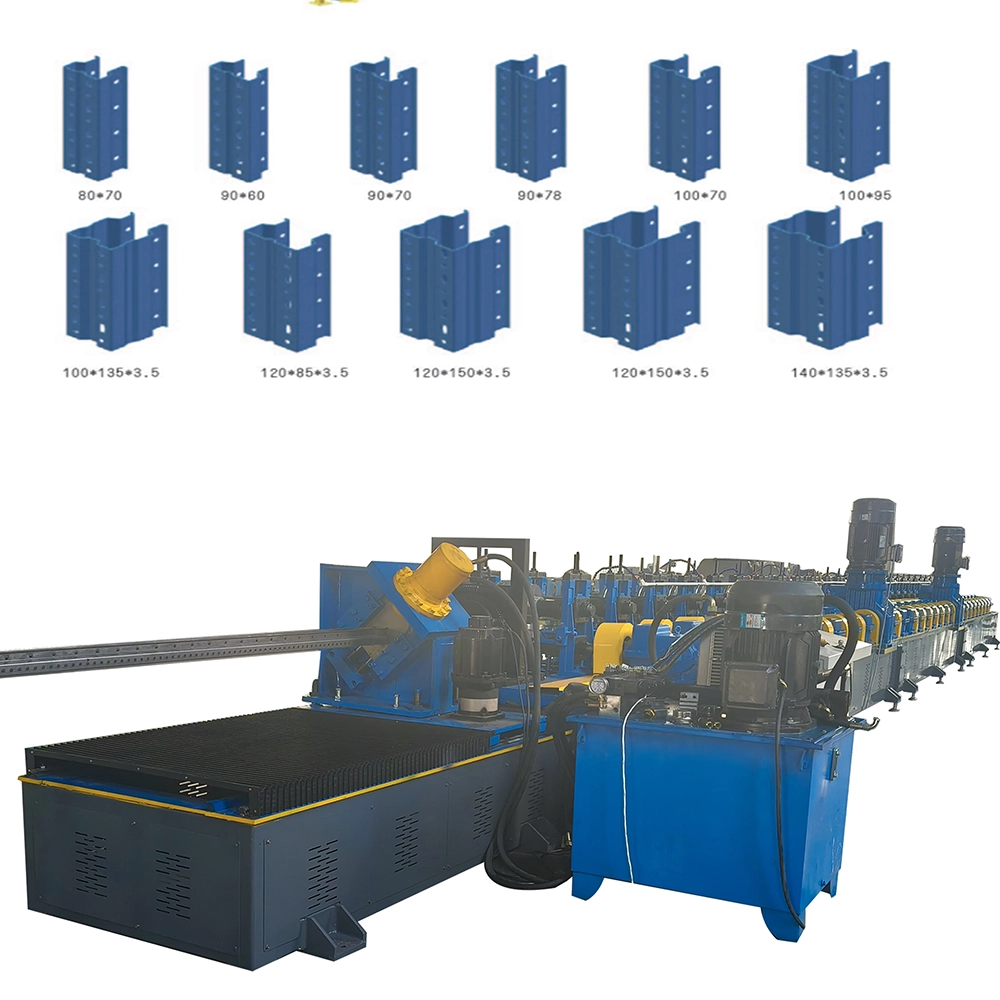

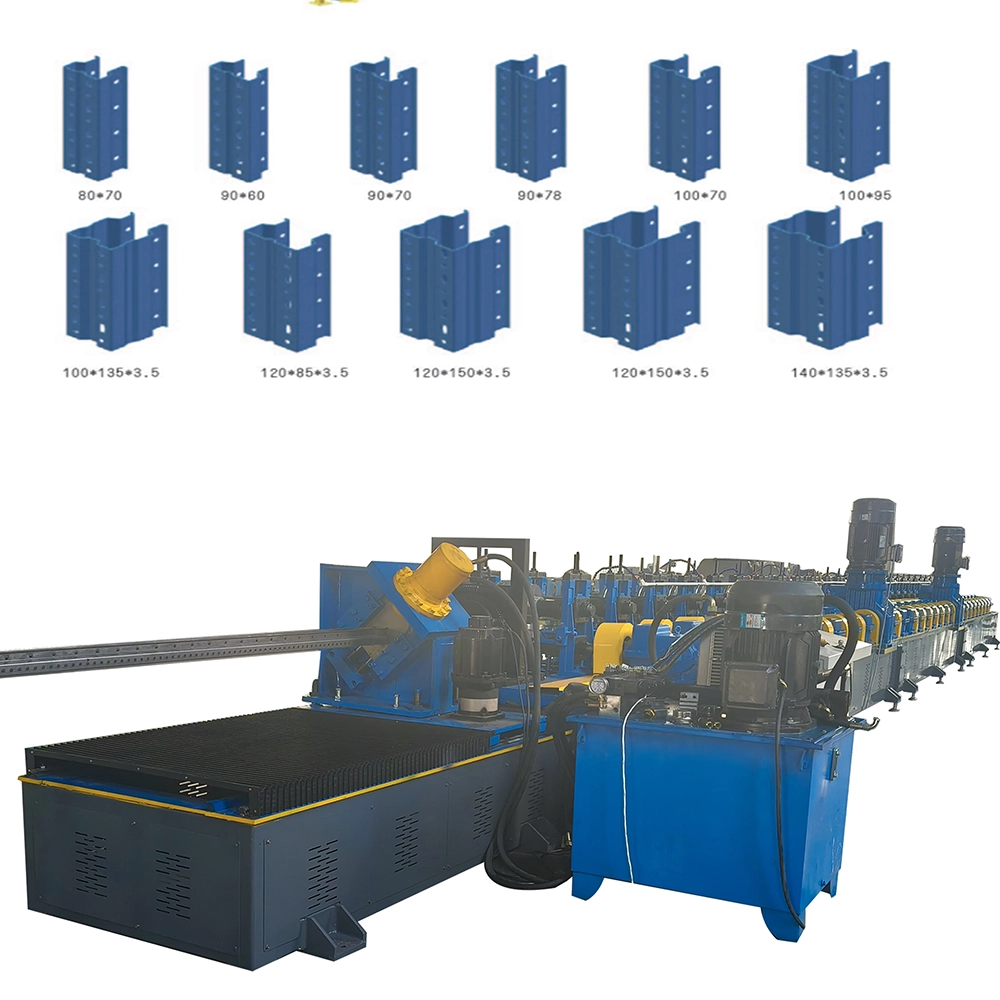

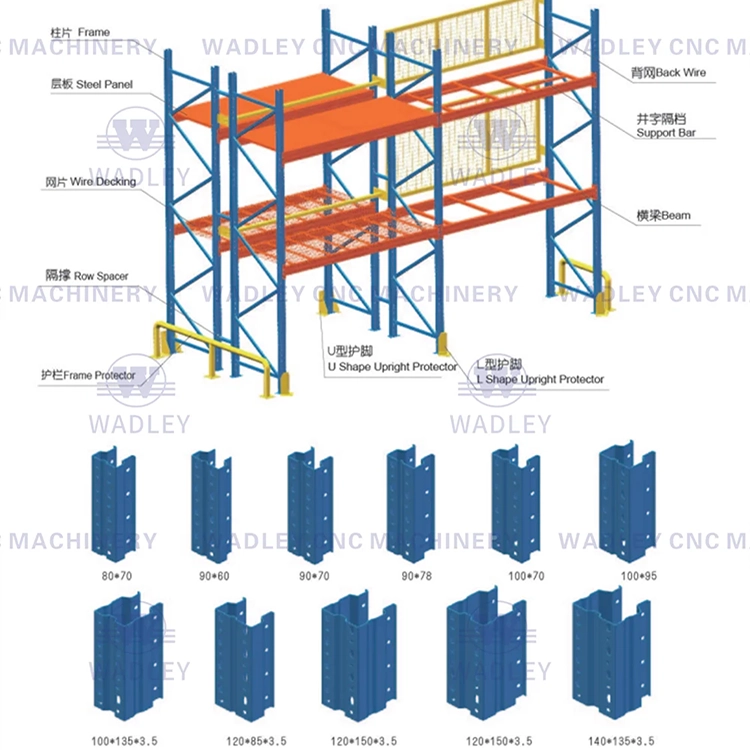

Heavy-duty Supermarket Storage Upright Rack Rolling Forming Machine

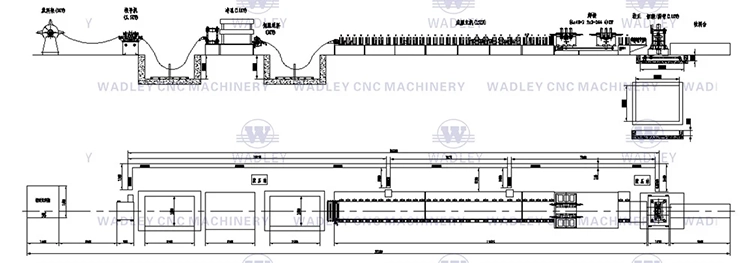

Heavy-duty storage shelf cold roll forming machine is the most popular shelf production line of Waldley Company. It not only has conventional sheet metal forming, and also has a necking process, which is currently the most popular new design and process in the global market.

Description

Heavy-duty storage shelf cold roll forming machine is the most popular shelf production line of Waldley Company. It not only has conventional sheet metal forming, and also has a necking process, which is currently the most popular new design and process in the global market. It effectively saves labor costs and makes shelf overlapping more convenient and fast.

High speed punching, in the case of multiple and dense hole positions, can achieve a punching speed of 20-30 meters per minute,

with high precision and fast speed.

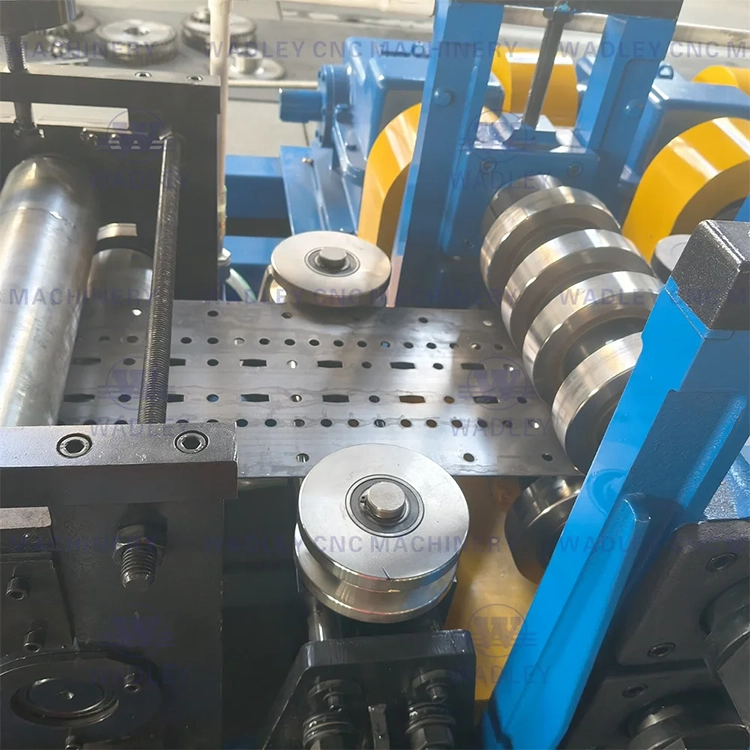

Product Details

Advantages of storage shelf forming machine and shelf forming equipment:

- 1 Highly automated procedures to reduce manual operation;

- 2 High work efficiency, improve enterprise productivity;

- 3 The production process of the whole process is stable to improve the quality and consistency of products;

- 4 Mass production reduces the production cost of enterprises.

Our technicians arrive at overseas customer sites for technical training and guidance:

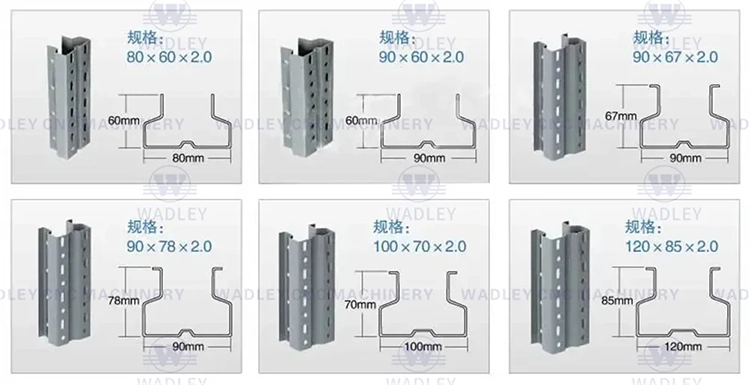

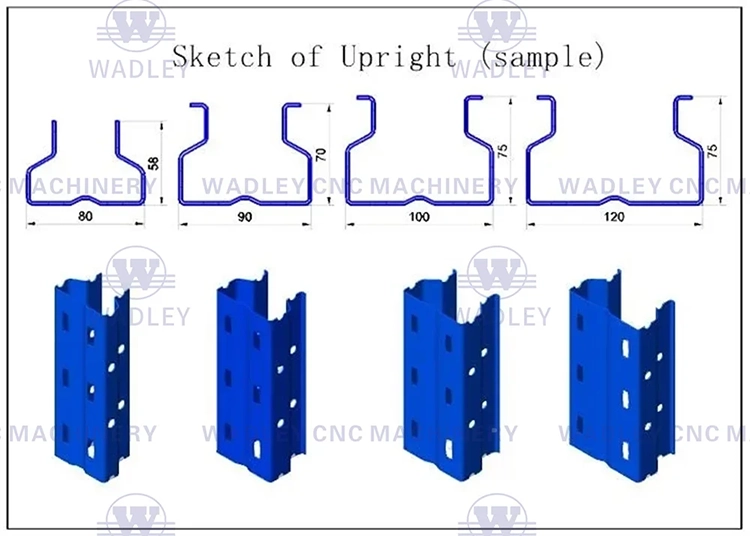

More profile and finished product displays:

Parameter

|

No. |

Item |

Data |

|

1 |

5T hydraulic decoiler |

Max 5T Max coil:800mm Hydraulic expansion and motorizied decoiling |

|

2 |

Holes Punching & corner cut |

We use hydraulic punching machine 2 sets Corner cut mould 1 set Lateral holes punching mould |

|

3 |

Logo stamping |

Stamping mould:1 set |

|

4 |

Roll forming Machine |

Wall Panel Catilever Structure 24 Forming Stations 15KW Motor Made In China |

|

5 |

Hydraulic Cutting&bending mould combination |

Cutting power:7.5kw Mould material:Cr12.HRC58-62 |

|

6 |

Run-out table |

Steel frame with Rollers |

|

7 |

Electric control panel |

PLC Control |

|

8 |

Suitable material |

Galvanized Steel Coils |

|

9 |

Material Thickness |

0.8-1.2mm |

|

10 |

Material width |

According to design deawing |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment