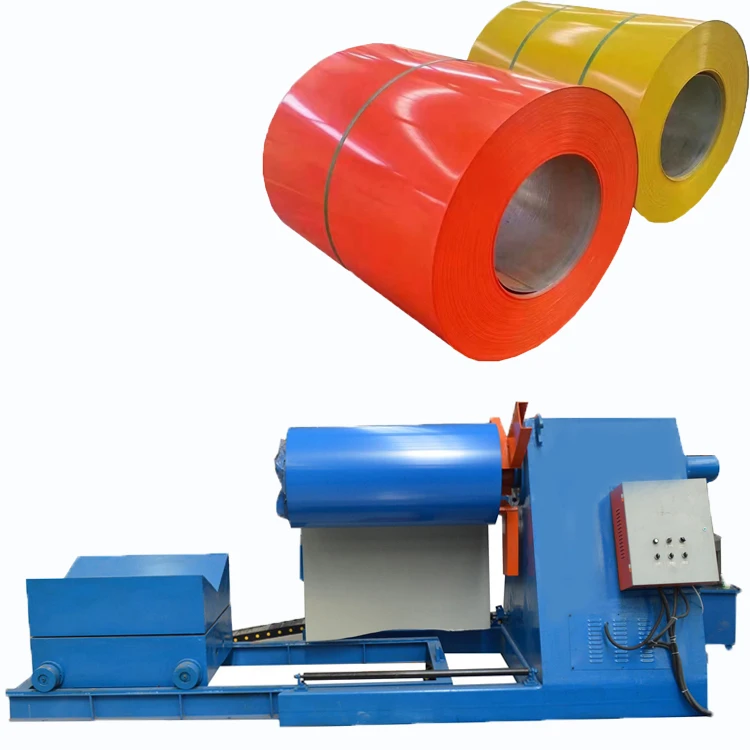

Hydraulic Uncoiler

Description

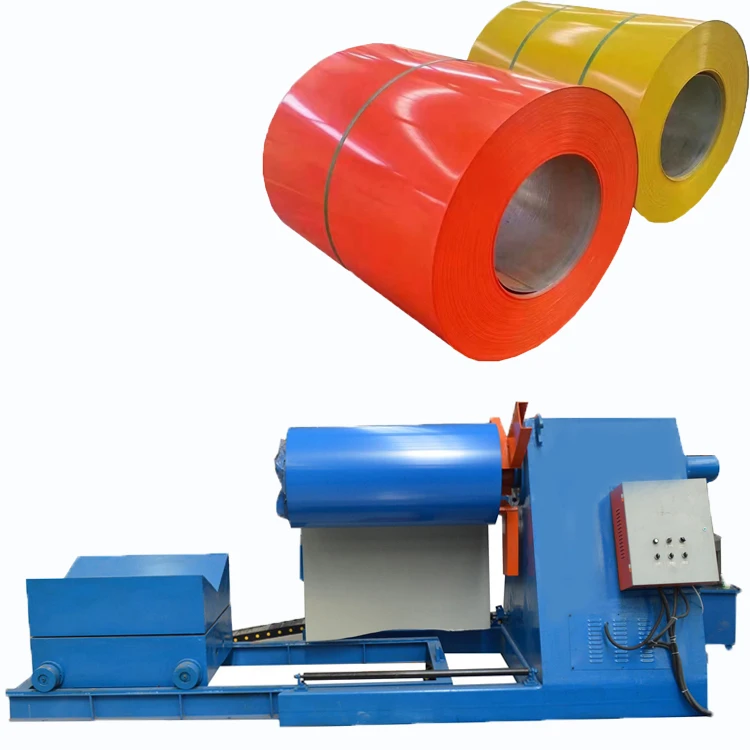

Hydraulic Uncoiler

A Hydraulic Uncoiler typically consists of a heavy-duty base, a coil loading car, a hydraulically driven mandrel (with expanding head), a hydraulic hold-down roll or guiding device, a hydraulic power unit, and an electro-hydraulic control system. Its operating principle involves the hydraulic power unit generating high-pressure fluid to drive a hydraulic motor, which rotates the mandrel for active pay-off. Simultaneously, hydraulic cylinders control the action of the hold-down roll to press against the coil's outer laps, preventing coil collapse and assisting in strip guidance.

Compared to electric uncoilers, hydraulic drives can provide smoother operation at very low speeds and significantly higher instantaneous starting/braking torque, offering greater tolerance to sudden load changes (e.g., weld joints in the coil). The system structure is relatively simpler and more robust, although it generally has slightly higher energy consumption and requires hydraulic fluid maintenance. This equipment is widely used in steel warehousing, thick plate preprocessing, heavy-duty slitting lines, and some traditional continuous production lines where reliability and power are prioritized over ultra-high control precision.

Product Details

- 1 iron drum cutted plate decoiler machine is an auxiliary equipment for roll forming machine. Separately working, through reducer by Chain driving the shaft to decoiling or recoiling the coil material. When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

- 2 Set electric control system separately, realized the extension of the center shaft of uncoiler machine, and driving the shaft forward, backward, and step motion forward and backward. The ancillary shoring is for supporting the main uncoiling machine so as to make the hydraulic decoiler's bearing capacity become larger.

- 3 he working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.

There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

Parameter

| Model | Units | MT-400 | MT-500 | MT-600 | MT-700 | MT-800 | MT-1000 | MT-1300 |

| Width | mm | 400 | 500 | 600 | 700 | 800 | 1000 | 1300 |

| Thickness | mm | 0.3-2 | 0.3-2 | 0.3-2 | 0.3-2 | 0.3-2 | 0.3-2 | 0.3-2 |

| Inner diameter | mm | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 |

| Outside diameter | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Loading weight | T | 45721 | 45721 | 45721 | 45721 | 37749 | 38574 | 38574 |

| Feeding speed | m/min | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| System | / | hydraulic聽 | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic |

| Weight | kgs | 1400 | 1600 | 1800 | 1900 | 2100 | 2300 | 2500 |

| Overall size聽 | m | 1.2*1.1*1.3 | 1.4*1.2*1.3 | 1.5*1.2*1.3 | 1.7*1.3*1.4 | 1.8*1.4*1.4 | 2.0*1.5*1.6 | 2.0*1.8*1.8 |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

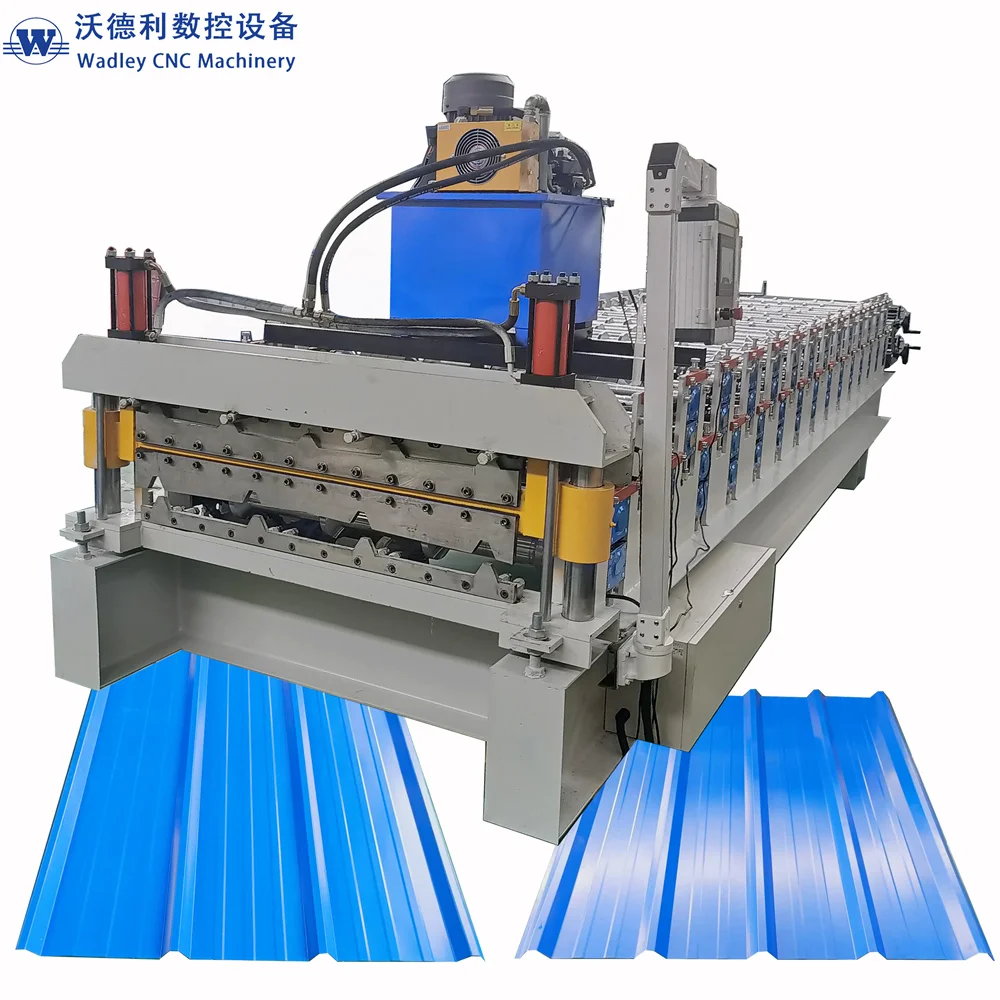

- Roof Froming Machine

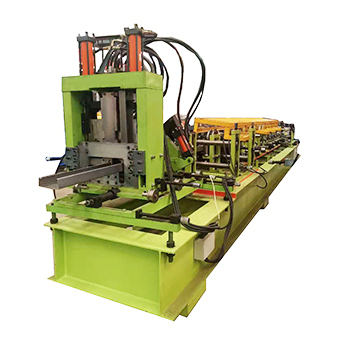

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment