Steel Coil Slitting Line

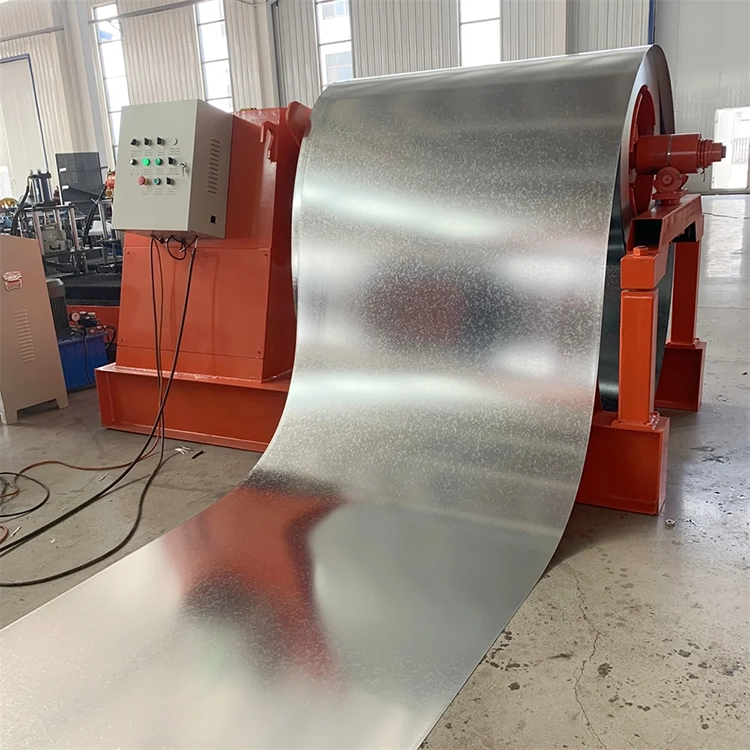

A Steel Coil Slitting Line is an automated processing system designed to continuously slit wide metal coils into multiple narrower strips longitudinally. Utilizing precision knives and control systems, it performs efficient, high-accuracy slitting operations and completes the recoiling and packaging processes. It is essential equipment in the metal processing industry for improving material utilization and adapting to diverse application requirements.

Description

Steel Coil Slitting Line

The Steel Coil Slitting Line is a core piece of equipment in metal finishing. Its standard configuration comprises: a loading car, uncoiler, entry guiding table, precision slitting head (with top and bottom arbors), scrap winder, independent tension control system, multiple mandrel recoilers, and a discharging device.

During operation, the wide coil is uncoiled, leveled, and fed into the slitting head, where it is longitudinally cut by a set of precisely arranged circular knives. The resulting narrow strips, under independent tension control, are wound onto individual recoiler mandrels to form neat and tight finished coils. The entire process is monitored by an automated control system (PLC/HMI), ensuring stable operation and precise parameter control.

This line is widely used in industries such as construction, automotive, appliance, and packaging to produce slit strips of specific widths for products including roofing/wall cladding systems, shelves, cable trays, pipes, and trim strips.

Product Details

- 1 This machine adopts PLC control, easy to operate, reliable performance and beautiful appearance. Set the parameters on the PLC control cabinet, the machine automatically leveling and cutting, easy to operate and save labor cost. The leveling and shearing machine cuts metal plates at fixed lengths according to customer requirements. Set the length on the Plc, and the calibrating and shearing machine cuts automatically, saving labor cost.

- 2 Maintain the sheet flat feed, the surface of the sheared sheet is smooth without scratches, the cut is flat, no falling

material, saving material cost. - 3 The slitting roller adopts Cr12Mov, heat treatment, durable material, smooth cut of the slitted sheet.

- 4 The laminating device can be added according to customers' requirements With push-pull grid guard above the main machine to protect the safety of employees.

- 5 Automatic stacking of finished products, saving labor,improve production efficiency.

Parameter

| item | value |

| Cutting Width (mm) | 50mm - 10000mm |

| Material Thickness(mm) | 0.3mm - 2mm |

| Cutting Speed(m/min) | 200mm - 1000mm |

| Coil Weight (T) | 10-20T |

| Voltage | 380V 50HZ 3Phase or based on customer's need |

| Rated Power | 11KW |

| Weight | 10000 |

| Frame material | 350H |

| Box thickness | 16mm |

| Protection grade | IP55 |

| Motor explosion-proof level | ExdIICT4 |

| Motor ratio | 0.196527778 |

| Control system | Tricrystal |

| slitting quantity | as customers requirement |

| Coil width | as customers requirement |

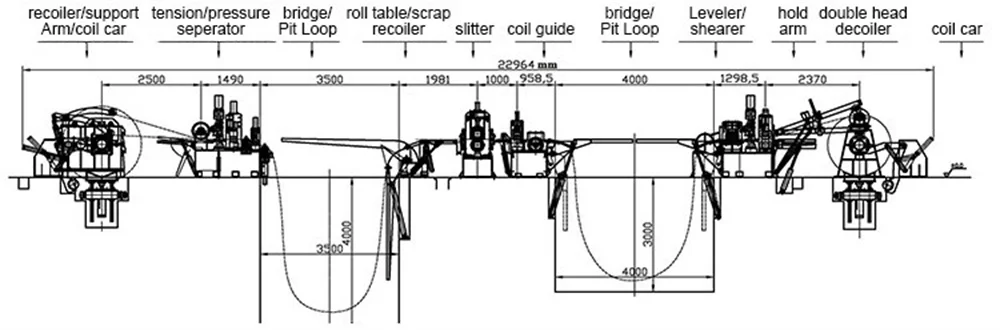

The Production Flow Of Automatic Metal Coil Slitting Line :

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment