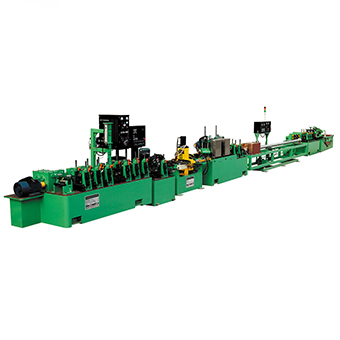

Steel coil leveling production line

Integrated at the entry stage of a roll forming machine, the leveling line typically consists of an uncoiler, a multi-roller leveler, and guiding control systems. Its core function is to apply successive and alternating bending stresses through a series of rollers, systematically correcting defects such as coil set, edge wave, crossbow, and camber. This process not only improves material uniformity but also reduces forming errors and residual stress, making it an essential stage in the production of high-precision profiled panels (e.g., roofing sheets and wall cladding).

Description

Steel coil leveling production line

The leveling production line in a roll forming machine is an integrated system designed to straighten and flatten coiled metal strips before they enter the forming stations. It typically consists of a decoiler, feeding guides, a multi-roll leveling unit (often with 5 to 13 rolls), and associated drive and control systems. The leveler applies alternating bending stresses to the material, effectively eliminating coil set, crossbow, camber, and other irregularities to ensure uniform flatness and dimensional accuracy. This process is critical for improving forming precision, reducing residual stress, and enhancing the overall quality of the final profiled sheet or panel.

Product Details

- 1 This machine adopts PLC control, easy to operate, reliable performance and beautiful appearance. Set the parameters on the PLC control cabinet, the machine automatically leveling and cutting, easy to operate and save labor cost. The leveling and shearing machine cuts metal plates at fixed lengths according to customer requirements. Set the length on the Plc, and the calibrating and shearing machine cuts automatically, saving labor cost.

- 2 Maintain the sheet flat feed, the surface of the sheared sheet is smooth without scratches, the cut is flat, no falling

material, saving material cost. - 3 The slitting roller adopts Cr12Mov, heat treatment, durable material, smooth cut of the slitted sheet.

- 4 The laminating device can be added according to customers' requirements With push-pull grid guard above the main machine to protect the safety of employees.

- 5 Automatic stacking of finished products, saving labor,improve production efficiency.

Parameter

| item | value |

| Type | Steel Coil Cut Length Machine |

| Use | Straightening & Leveling |

| Production Capacity | 30 m/min |

| Voltage | 380/415/440V |

| Rolling thinckness | 1-3mm |

| Feeding width | 1500mm |

| Dimension(L*W*H) | 18000*2000*2200 |

| Weight | 9800kg |

Inquiry

Please Feel to give your inquiry in the form.We will reply you in 24 hours.

- Roof Froming Machine

- Purlin Machine

- Shelf Forming Machine

- Door And Window Frame Forming Machine

- Downspouts Pipe Equipment

- Photovoltaic Bracket Forming Machine

- Fence And Flower Bed Making Machine

- Floor Deck Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Metal Pipe Making Machine

- Roof Ridge Cap Roll Forming Machine

- Gusset Plate Roll Forming Machine

- Car Panel Roll Forming Machine

- Bending And Shearing Machine

- Sandwidch Panel Forming Machine

- Cable Tray Roll Forming Machine

- Iron Plate Embossing Machine

- Roof Curing Machine

- Accessory-Equipment