The global metal sheet processing industry is undergoing a profound transformation, with intelligent, automated, and integrated solutions increasingly becoming mainstream. Within this trend, the roll forming machine sector, as a core equipment supplier, is experiencing an unprecedented wave of technological upgrades, offering global manufacturers higher production efficiency and new market opportunities.

Intelligent Upgrades: The Shift from Stand-alone Machines to “Mobile Factories”

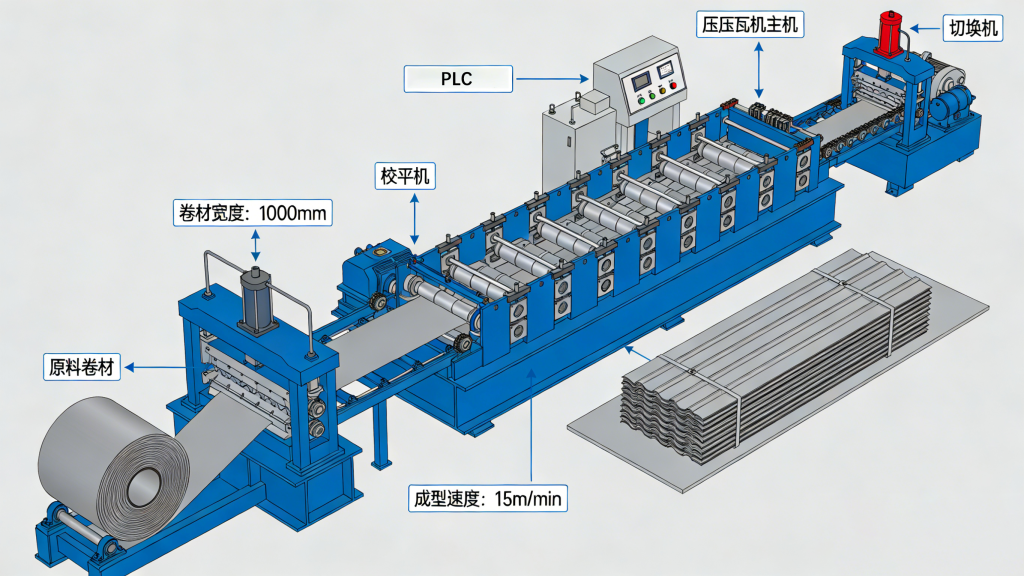

The traditional production process is being redefined. Leading manufacturers are no longer confined to selling single host machines. Instead, they provide integrated smart production lines by incorporating automatic feeding systems, palletizing robotic arms, and intelligent control modules. This upgrade allows an entire production line to be operated by just one worker, significantly reducing labor costs and boosting efficiency. Some innovators have even introduced “heavy-duty aerial work platforms” capable of lifting an entire roll forming machine to heights of 35 meters, enabling on-site production and installation of sheets directly on building rooftops. This achieves the leap from a “ground factory” to an “aerial mobile factory.”

The Automation Wave: Cobots Reshape Production

Facing a global shortage of skilled labor, automation has become an imperative. Collaborative robots (Cobots) are increasingly prevalent in bending and material handling. Compared to traditional industrial robots, Cobots offer advantages in flexible deployment, cost-effectiveness, and safe collaboration with human workers. The latest automated bending cells can achieve unmanned operation throughout the entire process—from sheet loading and bending to stacking. Advanced software systems automatically generate robot programs, drastically reducing programming and changeover time, making automation feasible even for small-batch, high-variety production.

Market Outlook: Efficiency and Flexibility Drive Future Demand

These technological innovations precisely address core global market demands: enhancing efficiency and increasing flexibility. On one hand, stable development in downstream industries like construction, automotive, and general machinery continues to drive equipment demand. On the other hand, customers are no longer satisfied with single-function machines, showing strong interest in integrated solutions that adapt to complex working conditions and reduce reliance on manual labor. It is foreseeable that roll forming products integrating intelligent control, remote diagnostics, and automation technology will gain stronger competitiveness and higher added value in the international market.